AtlanChannel is manufactured from a patented polymer mix that incorporates renewable resources, including recycled glass and street sweepings. These act as a bonded filler to enhance strength and durability.

Polymer channel drains are lighter than concrete alternatives, while maintaining rigid structure and compressive strength, which ensures they can support heavy loads and the rigors of high-use applications such as civil, transport and infrastructure projects. Their lightweight properties also provide carbon reductions and ease of installation, handling and freight compared to concrete channels.

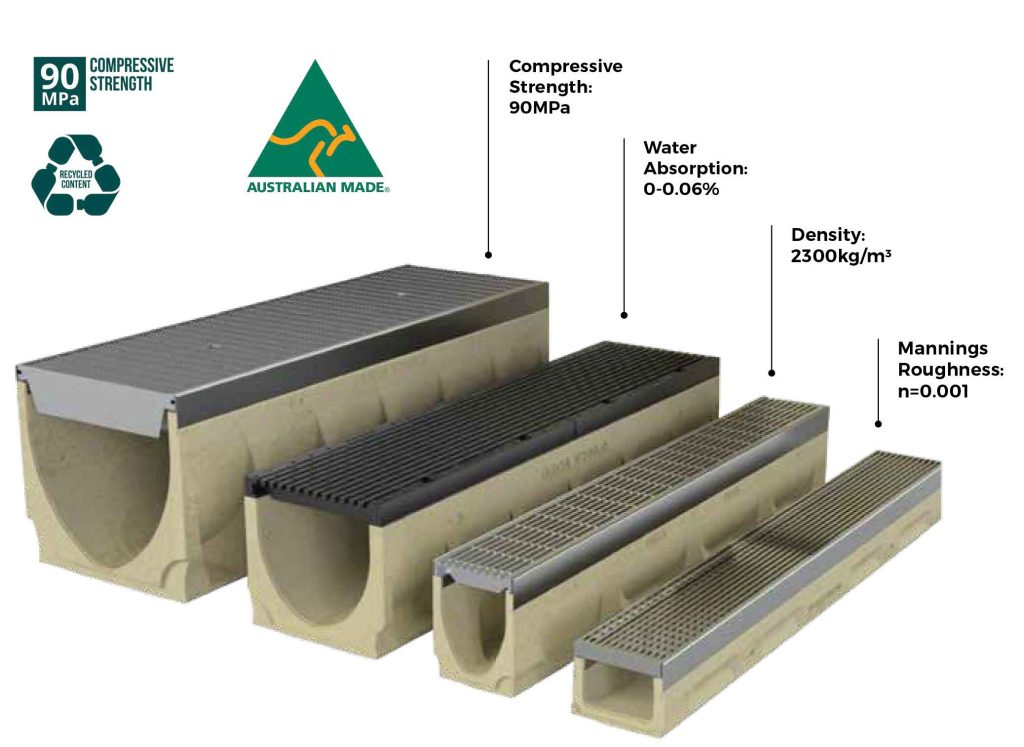

Technical data and key material properties for the AtlanChannel range include –

Density

The density of the AtlanChannel is approximately 2,300 kilograms per cubic metre – this is lighter than traditional concrete mixes which are over 2,400 kilograms per cubic metre.

Water Absorption

Due to the non-porous nature of polymer mixes, they exhibit an extremely low water absorption at 0-0.6%. This percentage shows the water weight gained by the material when it is wet, and this low absorption shows the suitability of AtlanChannel for drainage applications. High-quality, durable polymer material compositions are well-suited to resisting incoming flows.

Compressive Strength

AtlanChannel’s polymer concrete composition achieves up to three times the compressive strength of conventional concrete, with typical compressive strength around 90 MPa. This figure indicates the pressure the polymer mix can maintain before it fails or cracks and supports the AtlanChannel’s loading capabilities.

Hydraulic Roughness

The AtlanChannel’s polymer drainage system has a Manning’s roughness coefficient of n = 0.001, indicating a very smooth inner surface ideal for efficient water flow. This quantifies the frictions caused by internal drainage surfaces, with AtlanChannel’s polymer mix providing a very low roughness rating. Concrete is rough and porous in comparison, which negatively impacts water flow velocity and the rate at which drains empty.